Innovative Technology in Arcadia Custom’s Thermal Steel Products

The window and door industry has witnessed remarkable advancements in recent years, particularly in the realm of energy-efficient building components. Arcadia Custom’s Thermal Steel line of products stand out as an example of cutting-edge technology combined with architectural beauty.

Let’s take a look at the technology underpinning these innovative products and emphasize how they were engineered to meet or surpass current energy efficiency building codes. These advancements are crucial for both new construction and renovation projects.

Advanced Materials and Insulation

Arcadia Custom’s Thermal Steel windows and doors are engineered with a meticulous focus on materials and insulation technology. These components are key to meeting energy efficiency requirements.

- Steel Frames with Thermal Breaks: The use of steel in windows and doors provides structural strength and durability. However, steel is a conductor of heat, which can lead to energy loss. To combat this, Arcadia Custom incorporates thermal breaks into their steel frames. A thermal break is an insulating material placed between the interior and exterior surfaces of the frame. This technology significantly reduces thermal conductivity, minimizing heat transfer and increasing energy efficiency.

- Insulated Glazing: The glazing used in Thermal Steel products often features multiple layers of glass with low-emissivity (Low-E) coatings. Low-E coatings are designed to reflect heat back into the room while allowing visible light to pass through. Argon or krypton gas fills the space between the glass layers, further enhancing insulation properties by reducing convective heat transfer.

Precision Engineering and Manufacturing

Arcadia Custom employs state-of-the-art engineering and manufacturing techniques to ensure the precise fit and finish of their Thermal Steel windows and doors, enhancing energy efficiency.

- Computer-Aided Design (CAD) and Finite Element Analysis (FEA): These technologies enable engineers to design and simulate the performance of the products under various conditions, including thermal stress. FEA helps identify potential weak points and optimize designs for superior thermal performance.

- Robotic Welding and CNC Machining: Arcadia Custom utilizes robotic welding systems and computer numerical control (CNC) machining to achieve consistently high levels of precision in frame assembly. This precision ensures that frames are airtight, minimizing drafts and heat loss.

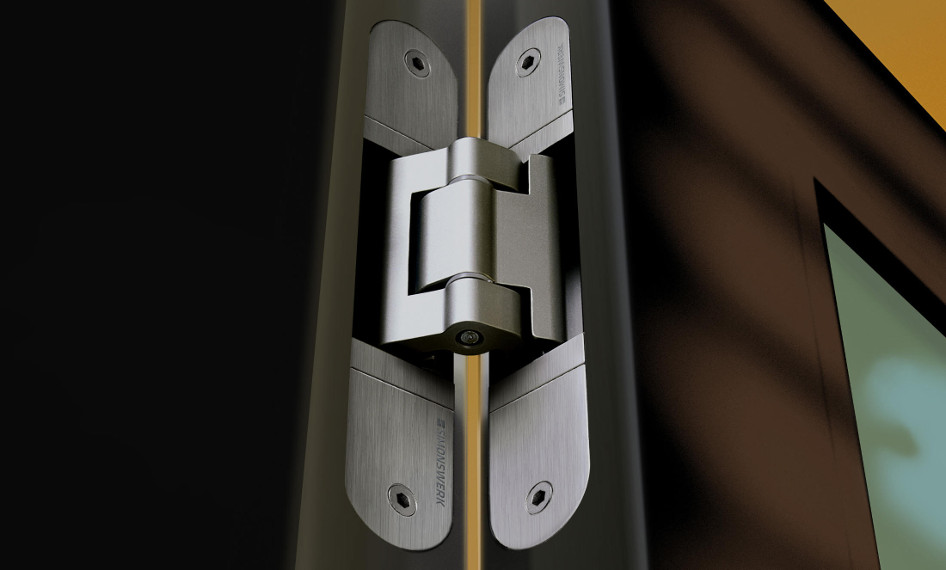

Energy-Efficient Hardware

The hardware components in Thermal Steel windows and doors contribute to their energy efficiency in several ways.

- Multi-Point Locking Systems: These systems offer enhanced security and also create a more effective seal, preventing air infiltration and reducing heat loss.

- Sill and Threshold Design: Arcadia Custom incorporates thermally broken sills and thresholds to minimize thermal bridging, a phenomenon where heat is conducted through a less insulated path, reducing energy efficiency.

Performance Testing and Certification

To ensure that Thermal Steel windows and doors meet energy efficiency building codes, Arcadia Custom subjects its products to rigorous testing and certification processes.

- NFRC Ratings: The National Fenestration Rating Council (NFRC) provides standardized ratings for windows and doors, including measurements of U-factor (thermal transmittance) and Solar Heat Gain Coefficient (SHGC). Arcadia Custom’s products are tested and certified by the NFRC to meet or exceed these standards.

- Thermal Cycling Tests: Products undergo thermal cycling tests to simulate real-world conditions, including exposure to extreme temperatures. This ensures that the windows and doors remain airtight and thermally efficient throughout their lifecycle.

Customization and Architectural Integration

While energy efficiency is a paramount consideration, Arcadia Custom also places a strong emphasis on design and architectural integration.

- Customization Options: The Thermal Steel line offers a wide range of customization options, including various frame finishes, hardware choices, and design configurations. This flexibility allows architects and homeowners to seamlessly integrate these windows and doors into diverse architectural styles while maintaining energy efficiency.

- Slim Sightlines: The design of Thermal Steel products includes slim sightlines, which provide a sleek and modern appearance while maximizing natural light intake. This design approach minimizes the amount of frame material that can conduct heat, further enhancing energy efficiency.

Meeting Energy Efficiency Building Codes

Arcadia Custom’s Thermal Steel windows and doors are engineered and manufactured with a commitment to meeting or surpassing energy efficiency building codes, which have become increasingly stringent in recent years. Here’s how they accomplish this goal:

- High Thermal Performance: The thermal breaks in steel frames, Low-E coatings, and insulated glazing combine to create windows and doors with low U-factors and SHGC ratings. These characteristics ensure that Thermal Steel products effectively resist heat transfer, contributing to energy efficiency.

- Air Tightness: Precision engineering and manufacturing processes result in tight seals and minimal air infiltration. This is crucial for complying with building codes, which often have requirements related to air leakage rates.

- Solar Heat Gain Control: By controlling the Solar Heat Gain Coefficient (SHGC), Thermal Steel windows and doors help regulate the amount of solar radiation entering the building. This is vital for meeting energy codes that aim to reduce cooling loads in warm climates.

- Comprehensive Testing: Arcadia Custom invests in comprehensive testing to validate the performance of their products. This includes assessments for thermal transmittance, air leakage, water penetration resistance, and structural integrity.

- Sustainability: Beyond mere code compliance, Thermal Steel products align with sustainable building practices. They contribute to reducing a building’s energy consumption, which is a core element of green building certifications like LEED (Leadership in Energy and Environmental Design).

Arcadia Custom’s Thermal Steel line of windows and doors represents the pinnacle of technological innovation and engineering prowess in the realm of energy-efficient building components. Through the use of advanced materials, precision manufacturing, and comprehensive testing, these products not only meet but exceed energy efficiency building codes for both new construction and renovations.

Are you convinced that Arcadia Custom products are the right choice for your new build or custom renovation? If so, contact a Northeast Architectural design specialist at (914) 630-7849 or click here to schedule a design consultation. If you’d like more information on Arcadia Custom windows and doors, click here to take a look